- Model NO.:

- H-1203

- Certification:

ntent="" style="background-color:#fee598;padding:0 10px;margin:0;line-height:36px;text-align:left;">Product Description

The Saturated Steam Retort is the oldest method of in-container sterilization used by human. For tin can sterilization, it's the simplest and most reliable type of retort. It is inherent in the process that all air be evacuated from the retort by flooding the vessel with steam and allowing the air to escape through vent valves.There is no overpressure during the sterilization phases of this process, since air is not permitted to enter the vessel at any time during any sterilization step. However, there may be air-overpressure applied during the cooling steps to prevent container deformation.

ntent="" style="background-color:#fee598;padding:0 10px;margin:0;line-height:36px;text-align:left;">Working principle

1. Load the full loaded basket into Retort, close the door. The retort door is locked through triple safety interlock to guarantee the safety. The door is mechanically locked throughout the whole process.

2. The sterilization process is automatically carried out according to the recipe of the input micro processing controller PLC.

3. In the beginning, steam is injected into the retort vessel through the steam spreader pipes, and air escape through vent valves. When both time and temperature conditions established in the process are met simultaneously, the process advance to come-up phase.In the whole come-up and sterilization phase, retort vessel is filled with saturated steam without any residual air in case of any uneven heat distribution and insufficient sterilization. The bleeders must be open for the entire vent, come-up, cooking step so that the steam can form convection to ensure the temperature uniformity.

ntent="" style="background-color:#fee598;padding:0 10px;margin:0;line-height:36px;text-align:left;">Detailed Photos

DTS patented tube heat exchanger. Inside tube material is stainless steel 316L, no need to replace the rubber gasket, no need maintenance, corrosion resistance, long service life.

Manual swing open door with safety interlock.

Option: Space-saving gullotinedoor with hydraulic driven.

Retorts have intrinsically safe door locking mechanisms with electrical switches interlocked with the internal vessel pressure.

ntent="" style="background-color:#fee598;padding:0 10px;margin:0;line-height:36px;text-align:left;">Product Parameters

| Model | Effective diameter | Effective length | Dimension | Qty of food baskets | Design Temperature | Design Pressure | ||

| L | W | H | ||||||

| DTSZ/12-3 | 1200 | 2400 | 3149 | 1852 | 2177 | 3 | 147ºC | 3.5bar |

| DTSZ/12-4 | 1200 | 3000 | 4216 | 2045 | 2538 | 4 | ||

| DTSZ/12-5 | 1200 | 4000 | 4500 | 2100 | 2500 | 5 | ||

| DTSZ/14-3 | 1400 | 3000 | 4500 | 2100 | 2500 | 3 | ||

| DTSZ/14-4 | 1400 | 4000 | 5680 | 2200 | 2701 | 4 | ||

| DTSZ/14-5 | 1400 | 5000 | 6500 | 2300 | 2700 | 5 | ||

| DTSZ/14-6 | 1400 | 6000 | 7600 | 2300 | 2700 | 6 | ||

ntent="" style="background-color:#fee598;padding:0 10px;margin:0;line-height:36px;">Our Advantages

1. Uniform heat distribution

By removing the air in the retort vessel, the purpose of saturated steam sterilization is achieved. Therefore, in the end of come-up vent phase, the temperature in the vessel reaches a very uniform state.

2. Comply with FDA/USDA certification

DTS has experienced thermal verification experts and is a member of IFTPS in the United States. It fully cooperates with FDA-approved third-party thermal verification agencies. The experience of many North American customers has made DTS familiar with FDA/USDA regulatory requirements and cutting-edge sterilization technology.

3. Simple and reliable

Compared with other forms of sterilization, there is no other heating medium for the come-up and sterilization phase, so only the steam needs to be controlled to make the batch of products consistent. FDA has explained the design and operation of the steam retort in detail, and many old canneries have been using it, so customers know the working principle of this type of retort, making this type of retort easy for old users to accept.

4. Full automatic linear control system

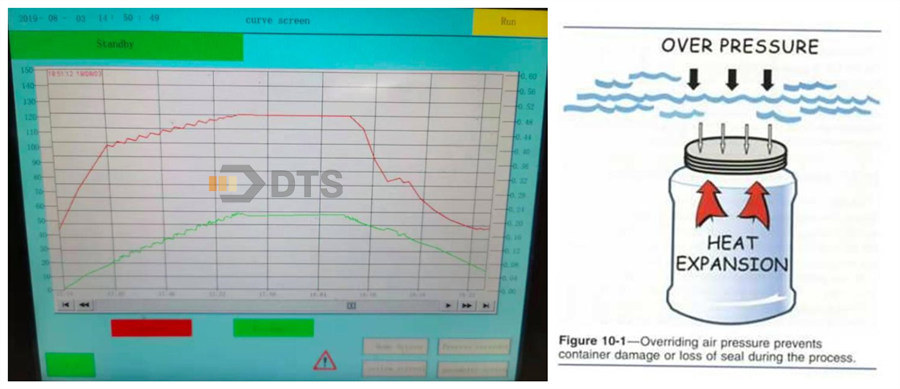

DTS self-studied patented technology D-TOP system can be sensitive to temperature.It can automatically calculate the pressure changes inside the container according to the temperature.And then automatically adjust the pressure inside the retort to get the pressure balance between container internal and external.So it can prevent the package's deformation, keep the package shape.Especially be suitable for aluminum tray products.Pressure was controlled in +/ -0.05 bar with compressed air intake valve and exhaust valve.

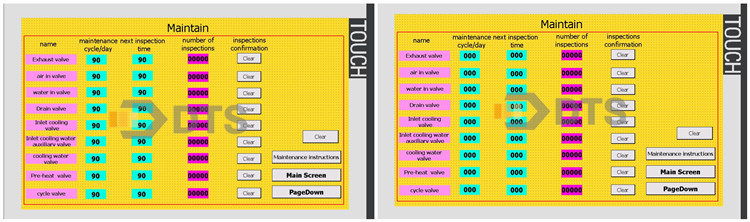

5. maintence cycle and alarm

For main valves, we set the maintenance cycle and time in the PLC, when it arrives, there will be alarm appear to notice.

ntent="" style="background-color:#fee598;padding:0 10px;margin:0;line-height:36px;text-align:left;">Packaging & Shipping

ntent="" style="background-color:#fee598;padding:0 10px;margin:0;line-height:36px;text-align:left;">Certifications

Retort is designed and produced according to the requirements of GB150-2011 <steel pressure vessel manufacturing standard>. DTS is identified and has passed through ISO9001, ISO14001 system authentication and also passed America ASME as well as SGS, TUV, BV, EAC rated.

1. Equipment is designed according to the GMP and FDA requirements.

2. If the cycle is based on the temperature data given by the cold spot location, if all products loaded have the same contamination level, we guarantee the less than 1/1,000,000 bags contamination.

ntent="" style="background-color:#fee598;padding:0 10px;margin:0;line-height:36px;text-align:left;">Company Profile

DTS is the most influential supplier of retort equipment in the food and beverage industry in Asia.Our goal is to become the top international brand in food sterilization industry.We have highly experienced and talent mechanical engineers, design engineers and electrical software development engineers.It is our aim and responsibility to provide the best products and services as well as excellent working environment for our customers.We love what we do, and we fully understand that our value lies in helping customers create value.To this end, we are cautious to develop and design various flexible and customized solutions to meet different customer needs through well communication.

The1year

The1year

Quality Side Spray Sterilization

Quality Side Spray Sterilization

Small Lab Pilot Retort Autoclave

Small Lab Pilot Retort Autoclave

Automatic Batch Retort System/Ste

Automatic Batch Retort System/Ste

Rotary Water Immersion Retort/Aut

Rotary Water Immersion Retort/Aut

Water Spray Retort Equipment/Auto

Water Spray Retort Equipment/Auto

Laboratory Retort/Autoclave/ Ster

Laboratory Retort/Autoclave/ Ster