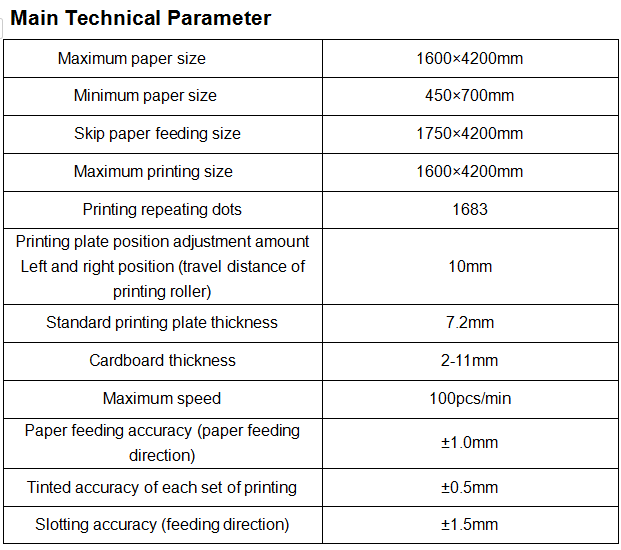

- Model:

- HP-LM1600

- Max cardboard feeding size:

- 1600*4200mm

- Economic speed:

- 100pcs/min

Automatic four color flexo printing machine with slotter and die cutter and stacker

Overall performance

1. The operating control voltage is AC380V, the frequency is 50Hz, the control circuit voltage is AC220V, and the panel switch voltage is DC24V.

2. The control panel is equipped with a 10.4-inch human-machine interface color touch screen, which can control the paper feeding section, printing section, slotting section, and die-cutting section, which is convenient, fast and high-precision. In addition, each assembly has a 7-inch color touch screen, which is more convenient Operation, computer control can store 999 frequently used orders, order replacement is faster, and operation is more convenient (independent computer console operation).

3. Order production volume setting. Operating speed display.

4. The memory is reset to zero. During the working process of the machine, if the machine needs to be turned on for plate cleaning or a small amount of plate change, it can automatically return to the original position after the machine is closed.

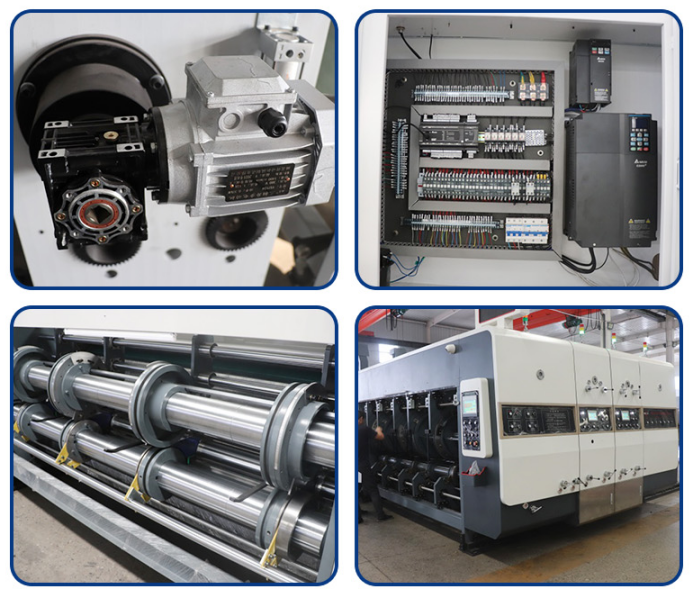

5. All drive rollers are made of high-quality steel, plated with hard chrome, and the surface is ground.

6. The transmission gear is 60mm thick and made of high-quality steel, with a Rockwell hardness of 58-62 degrees after heat treatment.

7. Each unit of the whole machine is separated as a whole or separately; continuous ringing warning when walking to ensure the safety of the operator. An emergency stop switch is installed in each unit to stop the movement of each unit inside to ensure the safety of internal operators.

8. Automatic oil balance device to keep the oil of each unit at the same level.

9. The wallboard of the main machine is made of HT250, with a thickness of 60mm after tempering treatment, and is made of a large machining center to ensure high strength and high precision.

1. Leading edge paper feeding system, frequency conversion control air volume, accurate and stable paper feeding.

2. Side baffle and front baffle linear guide rail traverse system, side-shooting and paper-aligning function.

3. The rear bracket is electrically controlled front and rear, and the bracket angle can be easily adjusted.

4. In addition to static electricity device, brush and synchronous lifting type dust suction device, dust removal is more perfect.

5. Single-row paper feed roller mode, quick-change mechanism for paper feed rollers.

6. The main control computer and unit man-machine control system.

7. Optional-adsorption transmission box, improve compression resistance, widened dust removal system, better effect.

8. Shandong Komori servo leading edge paper feeding system (four-axis).

1. Printing phase, main control computer and touch screen control.

2. Adsorption wheel box conveying, regulating air volume and air section to ensure smooth conveying.

3. Ceramic wheel surface transmission wheel, centralized oil injection lubrication device, to ensure accuracy and life.

4. Reel lock plate, locking device on the left and right sides, fast plate hanging drive.

5. The phase adopts an electromagnetic clutch fixing device, which automatically detects and resets. To

6. Set up a controlled circulating ink supply system, ink supply protection, ink shortage alarm, ink saving settings, and quick cleaning.

Optional: Double squeegee wiping system-better printing effect.

7. Dust-proof control box.

8. "Delta" series PLC, high-speed operation module and connection communication interface. 7-inch monochrome touch-sensitive unit operation man-machine interface, DC24V button and selector switch, frequency converter to adjust the air volume of cardboard transmission, unit sub-power non-fuse switch, motor start/stop and overload protection, control circuit protection switch.

1. Die cutting phase, main control computer and touch screencontrol.

2. Pneumatic toothed gap fixing device, electric gap and setting adjustment.

3. The rubber pad roller automatic displacement mechanism extends the service life of the rubber pad. imported quick-change rubber pads, easy to exchange and wear-resistant. The rubber pad grinding and correcting mechanism increases the usage rate of the rubber pad and reduces consumption.

4. Precise "set-control" speed difference compensation system to ensure die-cutting accuracy and wide compensation range.

5. Dust-proof control box. "Delta" series PLC, high-speed operation module and connection communication interface. 7-inch monochrome touch-sensitive unit to operate the man-machine interface. DC24V button and selector switch. The unit sub-power supply has no fuse switch. Motor start/stop and overload protection. Control circuit protection switch. The die-cutting unit is equipped with a zero reset button. The side and inner side moving knife operation panel of the die-cutting unit.

6. There are three operation modes of phase adjustment and registration, numerical setting, button quantitative or inching continuous. After the phase is set, the frequency converter will automatically adjust the speed, which has both accurate positioning and time saving.

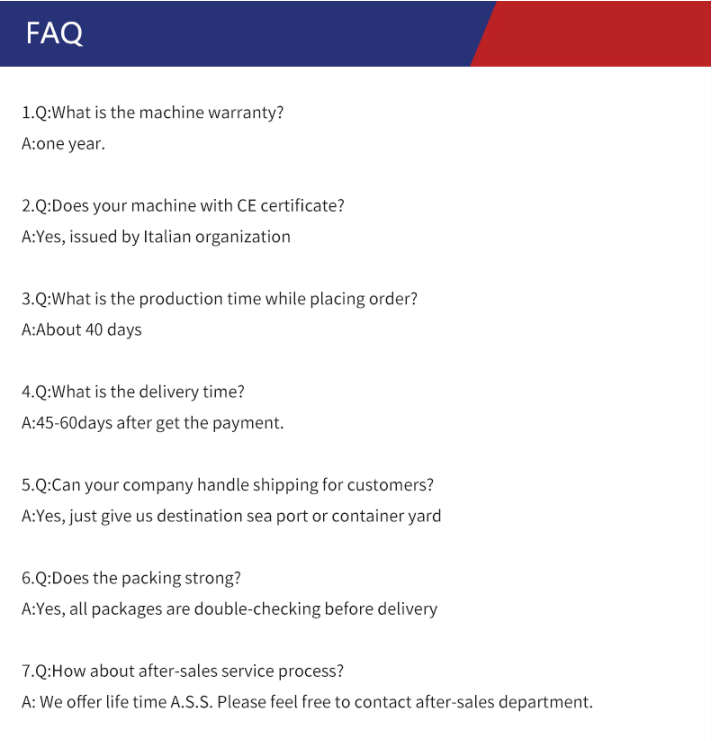

The1year

The1year

Carton Box Stitcher

Carton Box Stitcher

NC Cut off machine

NC Cut off machine

PE strapping machine

PE strapping machine

Carton Box Die Cutting Machine

Carton Box Die Cutting Machine

Semi-auto Die Cutting Machine

Semi-auto Die Cutting Machine

Rotary Die Cutting Machine

Rotary Die Cutting Machine

Cassette Single Facer

Cassette Single Facer