- Model NO.:

- W800

- Certification:

Basic Info

Model No.:100-1000t/d

Product Description

Soybean Meal Production Line

Soybean meal has high requirements for fat content, powder fineness, color and NSI value because it is extensively used as raw materials for production of SPC, SPI, histone and wiredrawing protein. We provide various soybean intensive processing lines, one of which is suitable for production of low temperature soybean meal.

1. Raw Materials: soybeans

2. Products: low temperature soybean meal (white soybean flake) (NSI is greater than 85%), soybean oil

3. Applications

Low temperature soybean meal (white flake) is widely used for production of soybean proteins such as SPI, SPC (protein content: higher than 50 percent, fat content: 0.5 percent)

4. Production Process

Cleaning, classifying, peeling, low temperature treatment, degreasing, desolventizing at lower temperature and low-temperature vacuum drying

5. Workshops (Production Sections)

Soybeans warehouse, cleaning and classifying workshop, low-temperature dehulling workshop, extraction and low-temperature desolventizing workshop, packing workshop and auxiliary workshops.

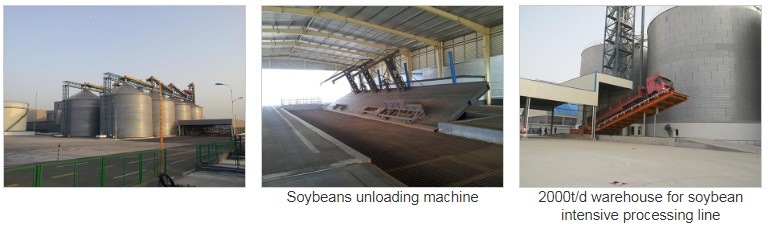

500t/d soybean intensive processing line in Russia

Process Workflow

Soybean Warehousing Section → Soybean Cleaning and Classifying Section →Low Temperature DehullingSection → Soy Extraction andLow Temperature DesolventizingSection

(1) Soybean Warehouse

Devices:soybeans unloading machine, preliminary cleaner, steel silo, elevator, conveyor, electrical control equipment, other auxiliary devices

Raw Materials:soybeans

Capacity:100-1000t/24h soybeans

Features

Full-mechanized operation is accomplished during soybeans transportation process, which significantly reduces production cost. To improve soybeans purity, we will remove large grained impurities and dust out of soybeans before putting them into relevant silos. The warehouse is equipped with machines, which are designed to aromatically put soybeans into silos, take soybeans out of silos and change soybeans silos.

(2) Cleaning and Classifying Workshop (Section)

Devices:rotary flat cleaning sieve, stoning machine, flat classifying screen, magnetic separator, online scale, dust removal equipment, rising conveyor, electrical control equipment and other auxiliary devices

Raw Materials:soybeans

Capacity:100-1000t/24h soybeans

Features

Cleaning sieve, stoning machine and magnetic separator are respectivelyused to remove organic impurities, stones, and iron particlesout of soybeans,which ensures superior product quality and prevents all these impurities from damagingrelevant mechanical equipment. Classifying screen is able to sort soybeans into differentgrades by size, thus further ensuring high quality of finished low temperature soybean meal. online scale accurately measures the weight of soybeans, which contributes to stable production and easy management. For clean production environment, dust removal equipment is equipped as well.

(3)Low-Temperature Peeling Workshop

Devices:drying tower, peeling machine, husk and kernel separator, kernel softening kettle, flaking mill, magnetic separator, dust removal equipment, rising conveyor, electrical control equipment and other auxiliary devices

Raw Materials:soybeans

Capacity:100-1000t/24h soybeans

Features

Soybeans softening and drying are all conducted at a lower temperature, which reduces steam consumption and causes less water-soluble protein loss. Peeling machine, along with husk and kernel separator, is able to completely and evenly remove soybean hulls, which facilities softening and flaking. The soybeans flakes obtained features uniform thickness and high tenacity, thus ensuring superior quality of finished low temperature soybean meal. Waste heat generated during the production process will be fully recycled for energy conservation. PLC automatic control system is adopted for control of critical parameters such as stock level, temperature, pressure, and flow rate.

(4)Extraction and Low-Temperature Desolventizing Workshop

Devices:extractor, horizontal desolventizing machine (A+B), vaporization system for oil mixture, solvent (steam) condensation recovery system, electrical control equipment and other auxiliary devices

Raw Materials:soybean flakes

Capacity:100-1000t/24h soybean flakes

Features

The extractor used is specially designed for production of low temperature soybean meal and it has many advantages. Made of flexible structural steel, horizontal desolventizing machine features great machining precision and high desolventizing efficiency. The whole leaching and desolventizing system works under micro-negative pressure. Waste heat created during the negative evaporation process will be fully recycled, which contributes to energy conservation. Exhaust gas generated during the production process will go through absorptive paraffin before emission, which is good for environment. PLC automatic control system is adopted for control of critical parameters such as stock level, temperature, pressure, and flow rate. Finished low temperature soybean meal features a small amount of residual oil, low less water-soluble protein loss and high quality. The efficiency of our production line has been strongly confirmed by multiple practical engineering projects.

Cases

Cases

We also provide the following project and equipment:

Oilseed Pretreatment Project

Oilseed Pressing Project

Oil Extraction Project

Oil Refining Project

Cottonseed Miscella Refining Project

Low Temperature and Edible Soybean Meal Project

Soy Protein Concentrate Project

Soy Protein Isolate Project

Looking for ideal Soybean Drying Softening Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Horizontal AB Desolventizer are quality guaranteed. We are China Origin Factory of Soybean Hulling Machine. If you have any question, please feel free to contact us.

The1year

The1year