- Model NO.:

- DGP90-B

- Certification:

1.Description

1. The fish feed making machine can make many kinds of fodder for different kinds of animal. It can make poultry-fodder, pet-fodder, as well as aquaculture fodder and fishery feed, which is also called floating feed.

2. The fish feed extruder is applied to the pretreatment of animal fodder, so as to reduce the loss of nutrition, and advance the protein content. So the fodder will be digested easier by the animals.

3. The poultry-fodder can feed chicken, rabbit, sheep, pig, and horse cattle and so on. The pet-fodder can feed dogs, cats, goldfish, etc. And the Fishery-feed can feed the fish, shrimps, crab, eel, catfish and so on.

2.Working principle

Feed material by feeding device, it will be pressed by the screw shaft under high pressure and temperature which makes the raw material fully puffed . Pellets can be different shape and size by changing the mold . Then cutting blades will cut the pellets into different length .

3.Features

1.Main parts adopt special alloy steel,dealed by heat treatment,long life time than usually machine.

2.Mold can be change easily ,can met different fish,shrimp,etc.

3.Without any adhesive.Floating fish feed can keep floating for more than 12hours without resolve,The floating time can be controlled by the puffing degree adjustment.

4.Adopt electric heating system improve feed expansion rate and delay the pellets floating time.

5.High temperature puffed process can kill the salmonellosis and bacterial infections,mean while make pellets easily digested.

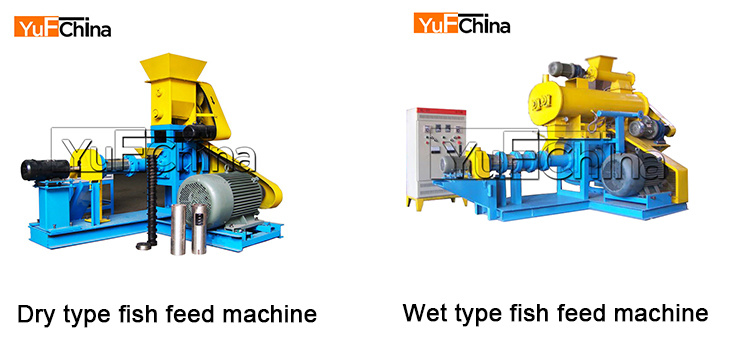

6.Different of dry type and wet type floating fish feed pellet machine :

Wet fish feed pellet machine need boiler to supply steam,dry type don't need boiler.

Dry type more cheaper than Wet type .

Wet type can produce much smooth and better quality feed pellet .

Pellet machine for making pet feed

4.Specifications

| Model | Capacity(kg/h) | Power(kw) | Screw diameter(mm) | Cutting power(kw) |

| DGP60-C | 120-150 | 15 | Φ60 | 0.4 |

| DGP70-B | 180-200 | 18.5 | Φ70 | 0.4 |

| DGP80-B | 200-250 | 22 | Φ80 | 0.6 |

| DGP90-B | 300-350 | 37 | Φ90 | 0.8 |

| DGP120-B | 500-600 | 55 | Φ120 | 2.2 |

| DGP135-B | 700-800 | 75 | Φ133 | 2.2 |

| DGP160-B | 1000-1200 | 90 | Φ155 | 3 |

| DGP200-B | 1800-2000 | 132 | Φ195 | 3-4 |

Our Services

Pre-sale

1. Depending on customer's requirement, we insist on "making profit at lowest investment" and gives best solution as per the customer's special demand.

2. Design the most reasonable project and maximum customers' profit.

3.Provide engineers to scene to plan work site if the customer needed.

4. Provide equipment list, design drawing, construction drawing, equipment install drawing.

During-sale

1. Depend on scene, draw design drawing , construction drawing, equipment install drawing, civil work detailed drawing for references, operating manuals, maintenance video, etc

2.Manufacturing products strictly on contract while customer constructing.

3. Production progress report each week with detailed description and photos, including raw materials tables, process and deep process record, testing data sheet, etc.

4. Testing all the equipments by witness of the customer ex-work, delivery, customer acceptance.

After-sale

1. Provide engineer to work site guiding install, debugging and commissioning.

2. Test equipment after installation, training operators for free, remind notice in operating.

3. Regularly returning visit to the customers.

4. Within warranted period, we take charge of everything if any quality problems. After the warranted period, we still focus on the plant running and services.

5. Response customer's questions within 1 working day, give effective solutions within 3 working days, go into action with 5 working day.

That's our promise, as we know quality and service both are important for long-term's development and cooperation.

Welcome to know more about our fish feed processing machine.

The1year

The1year