- 1000*250:

- 2600*1800*2800CM

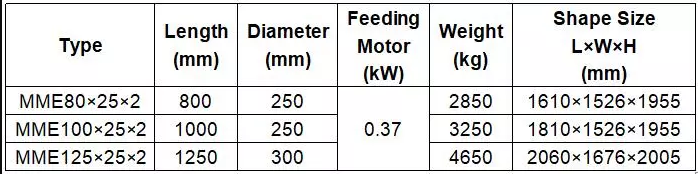

Roller Mill for Wheat Maize Flour Milling Factory

Commercial Grain Industrial

Roller Mill for Wheat Maize Flour Milling Factory Hasen Products

DescriptION OF ROLLER MILL IN WHEAT MAIZE FLOUR MILL FACTORY

1. Purpose and scope of application:

used for grinding wheat, corn, sorghum, etc. It is also suitable for crushing raw materials in wineries.

The machine has a stable gauge adjustment mechanism, not only suitable for short powder road production

line, but also suitable for long powder road production.

2. Main specifications and technical parameters:

parameters are divided into: 600, 800, 1000, 1250mm Single deck and double deck roller mill, Double deck

with 8 rollers.

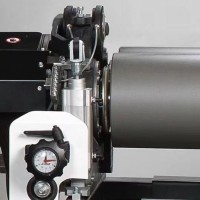

3. Structural features:

2. The upper steel plate is used to weld the lower cast iron bearing. The grinding roll group is installed

on the cross beam of the lower cast iron frame. The grinding stress is closed and self-supporting, which

is beneficial to the stability of the rolling distance and the reduction of noise.

achieve rapid roll change.

and slow rollers to meet the technological requirements of different users.

the housing. The structure is compact, the appearance is beautiful, and the operation is safe and reliable.

4. The working principle of the main structure is:

drive after passing the fast roller pulley 3, the slow roller pulley 4 and the tension pulley 5, realizes

the main movement of the grinding roller. The 7 speed ratios of different process requirements can

be obtained by replacing the speed roller belt 3 and 4. Various speed ratios are shown in Table 2.

2.The feed roller 8, the tension wheel 9, the feed roller triangle pulley 10 on the slow roller shaft are

transferred to the front feed roller (shunt roll) by the claw clutch 11, and then the rear roll (quantitative roll)

is driven by the single-sided synchronous toothed belt and the pulley 6 and 7. To change the speed of the

feed roller, only the triangle pulley 10 and the triangle belt need to be replaced, and the feed pulley is

matched.

See Table 3 for details.

Roller mill is used to break and crush the wheat and it is one of the most important machines in a flour mill.

Other name: wheat grain roller mill grain grinder grain grinding machine flour milling industry machine flour

mill rolls.

Features

- Cast iron structure can minimize vibration and noise.

- Equipped with SKF (Sweden) roller bearings to make sure stable running

- There are two series of roller mills. One is pneumatic control (MMQ) and the other is electrical control (MME).

The main difference is the feeding roll of MMQ series is driven by pneumatic components while MME series

by one small motor.

- Widely used for processing common wheat, buckwheat, durum wheat, maize, rye, barley, spelt, millet

and sorghum.

Technical Data-Electrical control

For Example: 150 tons per day wheat flour mill machine line :

The parameter for 150T/D Wheat Flour Mill Machine

1 Length of the roller 1000mm 2 Capacity(wheat/24h)150T/24h 3 Flour extractionTo produce standard flour: 75-82% To produce grade 2 flour: 70 -75% To produce grade 1 flour: 60-65% 4 Flour quality: Obey the people's republic of china's GB1355-88 standard5Power supply

|

The1year

The1year

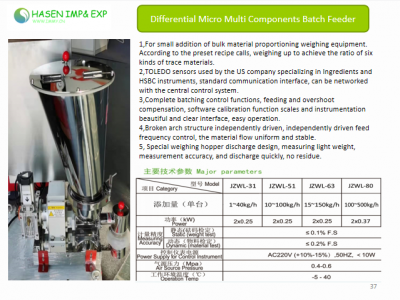

Multi vitamin batch feeder

Multi vitamin batch feeder

Oats Flakes Production Line

Oats Flakes Production Line

MOISTURE MEASURING DEVICE

MOISTURE MEASURING DEVICE

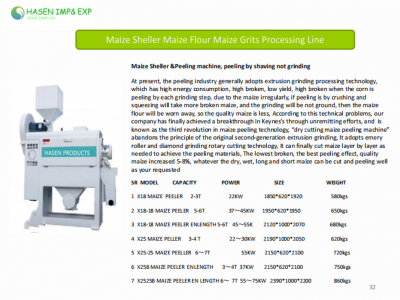

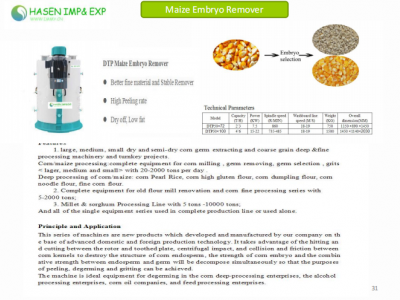

maize embryo removal

maize embryo removal

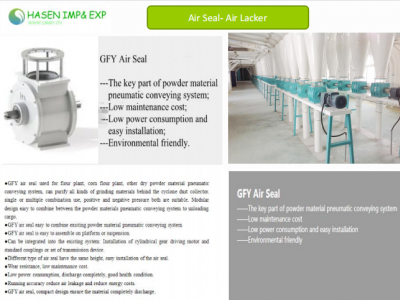

AIR LOCKER For maize flour

AIR LOCKER For maize flour

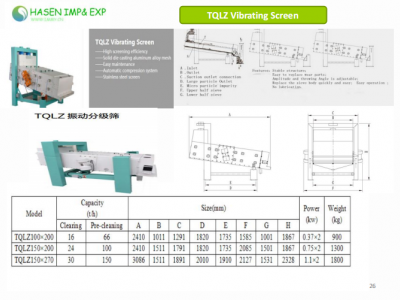

maize rotation sifter

maize rotation sifter

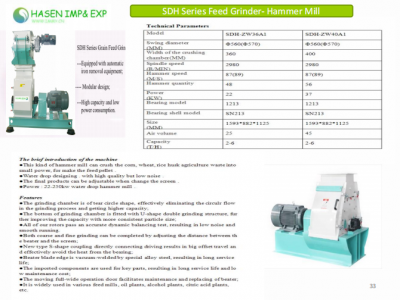

Grinder hammer mill

Grinder hammer mill

Buckwheat Seed Machine

Buckwheat Seed Machine

Eye Observation pipe

Eye Observation pipe