- Name:

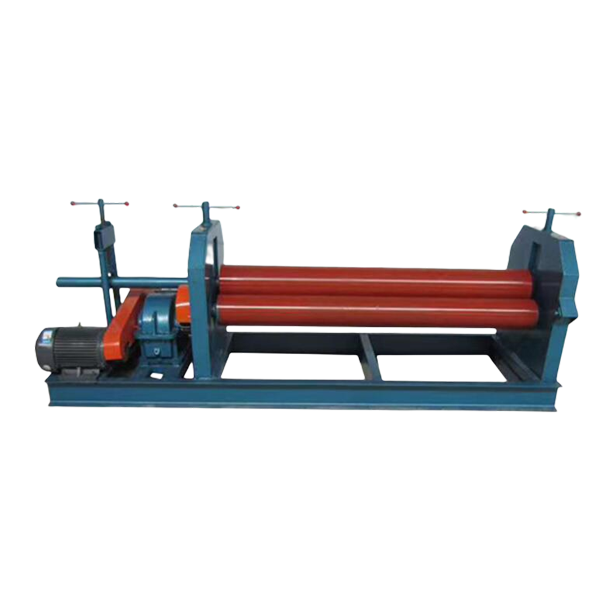

- Rolling machine

- Rolling thickness:

- 4mm – 30mm

- Bending Width:

- 1500mm – 4000mm

W11 Mechanical 3-roller symmetrical Rolling machine

Three roller symmetrical type

Easy operation and maintenance

Economical

W11 series mechanical symmetrical 3-roller rolling machine has 3 symmetrically arranged rolls and the upper roll is located at the center of two lower rolls.

A worm and gear drive and a screw rod and screw auxiliary drive are used to drive rolls to move vertically.

Rolling thickness: 4mm – 30mm

Bending Width:1500mm – 4000mm

W11 3-roller Rolling machine Features

Mechanical 3-roller symmetrical plate rolling machine.

The machine is composed of two main parts, there are working parts and the transmission parts. Working parts include two lower rollers and one upper roller with roller bearings. The lower roller is the capstan, the upper roller is a driven roller. The height of the upper roller can be adjusted freely. Besides, the transmission part contains the main motor, reduction box, etc.

The main motor drive the main reduction box, and then the main reduction box drives the lower roller. The direction of rotation of the lower roller can be controlled by the main motor.

The subsidiary motor drives the subsidiary reduction box, then the upper roller could perform a vertical movement.

Unloading equipment can help operators take out finished products.

W11 3-roller Rolling machine Technical Specification

| Model | Max Roll Thick. | Max Roll Width | Min Roll Dia. | Yield Limit | Roll Speed | Upper Roller Dia. | Bottom Roller Dia. | Lower Roller Center Distance | Main Motor Power | L*W*H | Weight | |

| <450N/mm2 | <700N/mm2 | mm | N/mm | N/mm2 | m/min | mm | mm | mm | Kw | mm | T | |

| W11-4/1500 | 4 | 2.5 | 1500 | 187.5 | 245 | 5 | 150 | 140 | 200 | 4 | 3050*860*1070 | 1.7 |

| W11-4/2000 | 4 | 2.5 | 2000 | 200 | 245 | 5 | 160 | 150 | 220 | 4 | 3500*950*1200 | 2 |

| W11-6/1500 | 6 | 4 | 1500 | 200 | 245 | 5 | 160 | 150 | 220 | 4 | 3000*750*1200 | 2.2 |

| W11-6/2000 | 6 | 4 | 2000 | 212.5 | 245 | 5 | 170 | 160 | 220 | 5.5 | 3500*900*1150 | 2.5 |

| W11-6/2500 | 6 | 4 | 2500 | 225 | 245 | 4.5 | 180 | 170 | 250 | 5.5 | 4050*910*1150 | 2.6 |

| W11-6/3000 | 6 | 4 | 3000 | 380 | 245 | 4.5 | 240 | 160 | 280 | 7.5 | 5000*950*1260 | 4.5 |

| W11-8/1500 | 8 | 5 | 1500 | 212.5 | 245 | 5 | 170 | 160 | 220 | 5.5 | 300*900*1150 | 2.4 |

| W11-8/2000 | 8 | 5 | 2000 | 225 | 245 | 4.5 | 180 | 170 | 250 | 5.5 | 3500*850*1150 | 2.5 |

| W11-8/2500 | 8 | 5 | 2500 | 300 | 245 | 4.5 | 240 | 180 | 280 | 7.5 | 4350*950*1250 | 4 |

| W11-12/2000 | 12 | 8 | 2000 | 300 | 245 | 4.5 | 240 | 180 | 280 | 7.5 | 3900*1200*1350 | 3.5 |

| W11-12/2500 | 12 | 8 | 2500 | 325 | 245 | 4.5 | 260 | 220 | 320 | 11 | 4300*1285*1400 | 5.3 |

| W11-12/3000 | 12 | 8 | 3000 | 350 | 245 | 4 | 280 | 240 | 360 | 11 | 5100*1350*1350 | 7.5 |

| W11-16/2000 | 16 | 10.5 | 2000 | 325 | 245 | 4.5 | 260 | 220 | 320 | 11 | 3850*1250*1300 | 4.8 |

| W11-16/2500 | 16 | 10.5 | 2500 | 350 | 245 | 4 | 280 | 240 | 360 | 11 | 4500*1600*1450 | 6.7 |

| W11-16/3000 | 16 | 10.5 | 3000 | 425 | 245 | 4 | 340 | 270 | 440 | 15 | 5700*1600*1750 | 10.3 |

| W11-20/2000 | 20 | 13 | 2000 | 350 | 245 | 4 | 280 | 240 | 360 | 11 | 4000*1450*1450 | 6.5 |

| W11-20/2500 | 20 | 13 | 2500 | 425 | 245 | 4 | 340 | 270 | 440 | 15 | 4700*1530*1680 | 9.3 |

| W11-25/2000 | 25 | 16.5 | 2000 | 425 | 245 | 4 | 340 | 270 | 440 | 15 | 4300*1600*1650 | 8.6 |

| W11-25/2500 | 25 | 16.5 | 2500 | 462.5 | 245 | 4 | 370 | 280 | 480 | 22 | 5780*1650*1962 | 11 |

| W11-30/2000 | 30 | 20 | 2000 | 462.5 | 245 | 4 | 370 | 280 | 480 | 22 | 5280*1650*1962 | 10 |

| W11-30/2500 | 30 | 20 | 2500 | 525 | 245 | 4 | 420 | 360 | 550 | 30 | 5240*1750*2070 | 16 |

| W11-30/3000 | 30 | 20 | 3000 | 187.5 | 245 | 4 | 150 | 390 | 600 | 30 | 5700*1750*2300 | 18.5 |

| W11-40/2500 | 40 | 26.5 | 2500 | 625 | 245 | 4 | 500 | 400 | 600 | 37 | 5300*1900*2400 | 20 |

Main Components of W11 3-roller Rolling machine

| Product type: | Mechanical |

| frame material: | Carbon steel Q235/Q345 |

| Motor: | BEIDE motor |

| Electrical part: | SIEMENS |

| Roller material: | 42CrMo/45# steel |

| Feature: | Low price, durable, low maintenance costs |

| Color: | Can be customized |

| Drop end: | Can be hydraulic |

Application Industries

This series of machines can roll metal sheets into cylindrical, arc, sector, cone and other workpieces. It is a general equipment specially used for sheet metal bending, forming, and correction. It is used in shipbuilding, chemical industry, boilers, water and electricity, pressure It has a wide range of applications in various industries of container and machinery manufacturing.

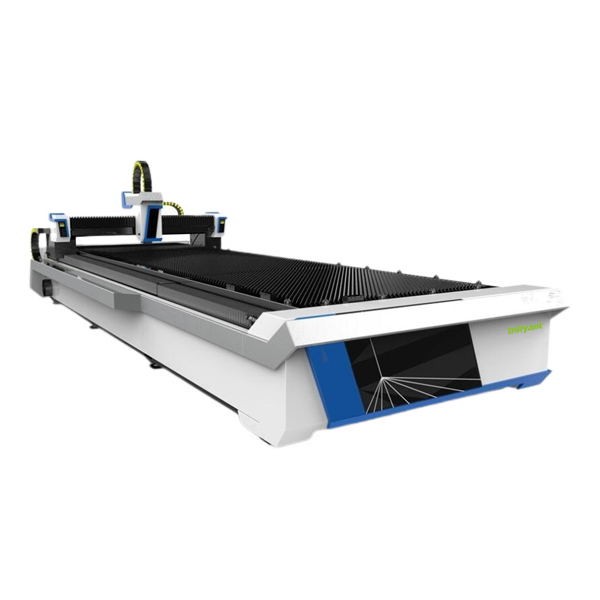

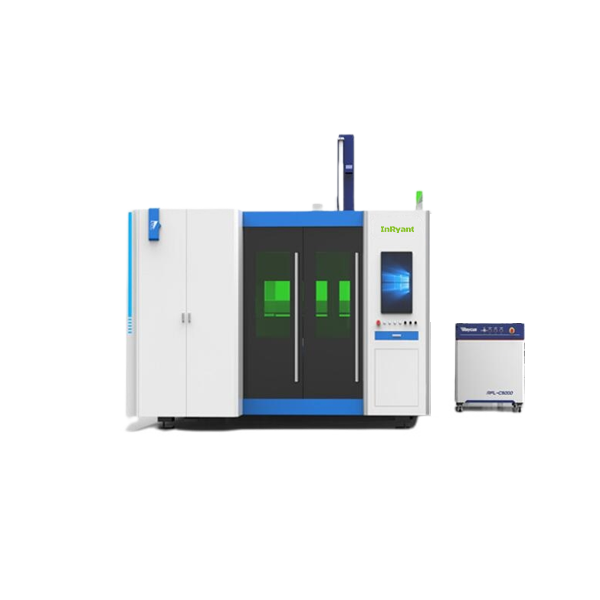

Quality Control

InRyant CNC Tech meets the demands of customers for high-quality products with a strict quality control system.

Our factory has advanced test equipment and a team of excellent mechanical engineers.

We also ensure the stability and traceability of the spare parts, so as to get excellent products with superior quality.

Through strict quality management, the factory controls potential quality risk from the beginning to the finishing of machines.

Get in Touch

Are you interested in our products? A sales executive will contact you within 24 hours.

Business Emails: info(at)inryant.com

WhatsAPP:+8613265157984

The1year

The1year