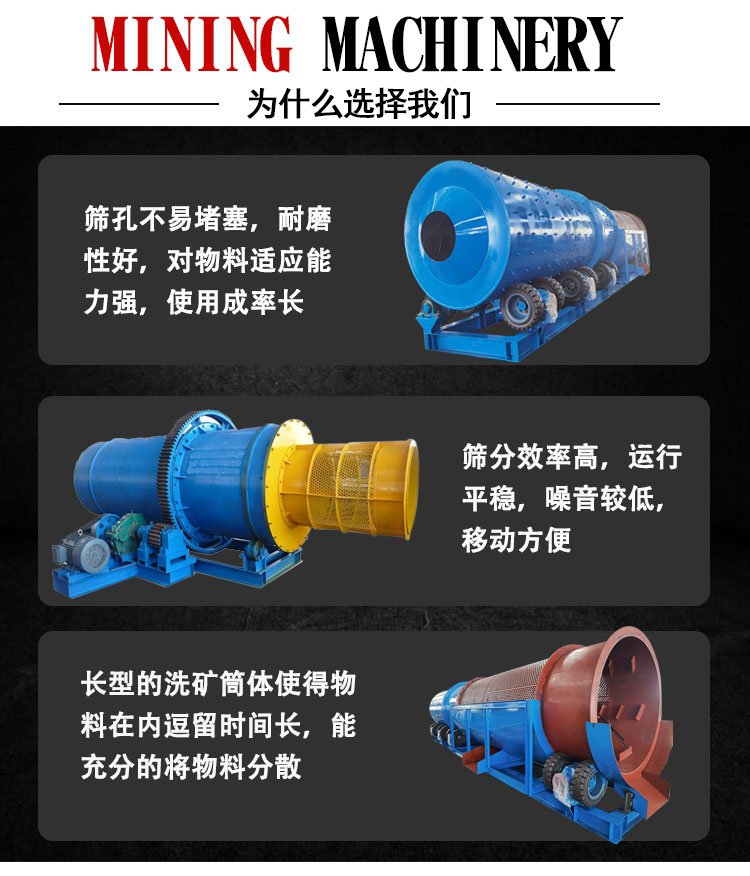

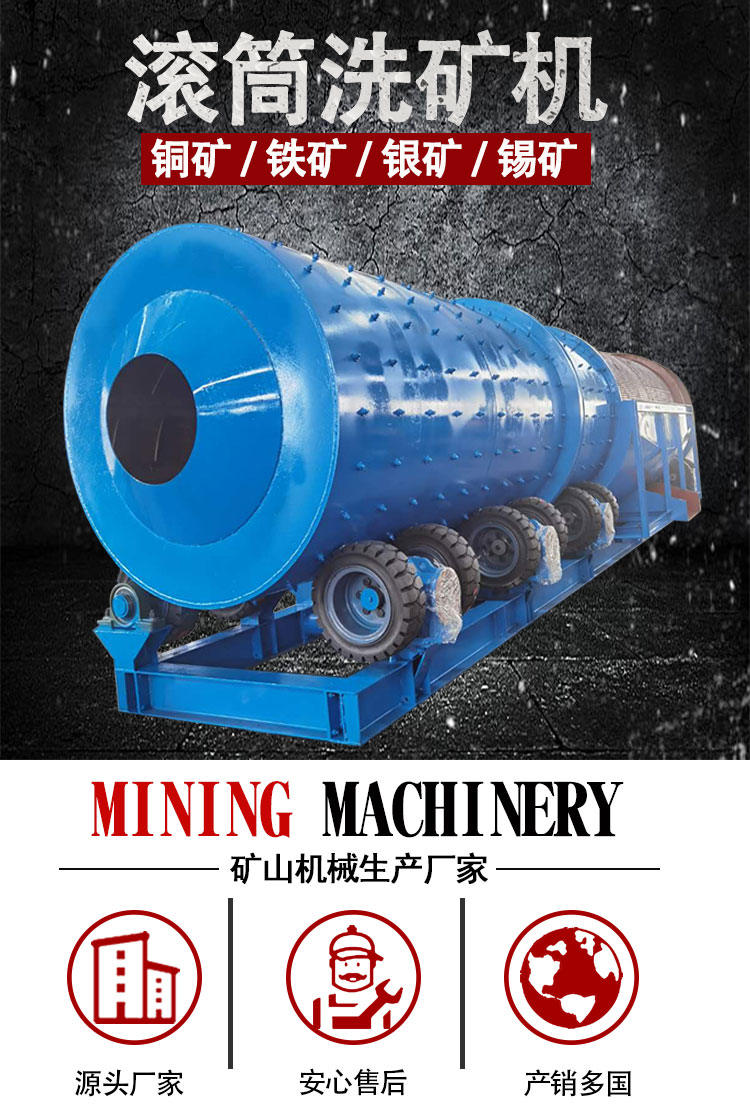

Drum washer

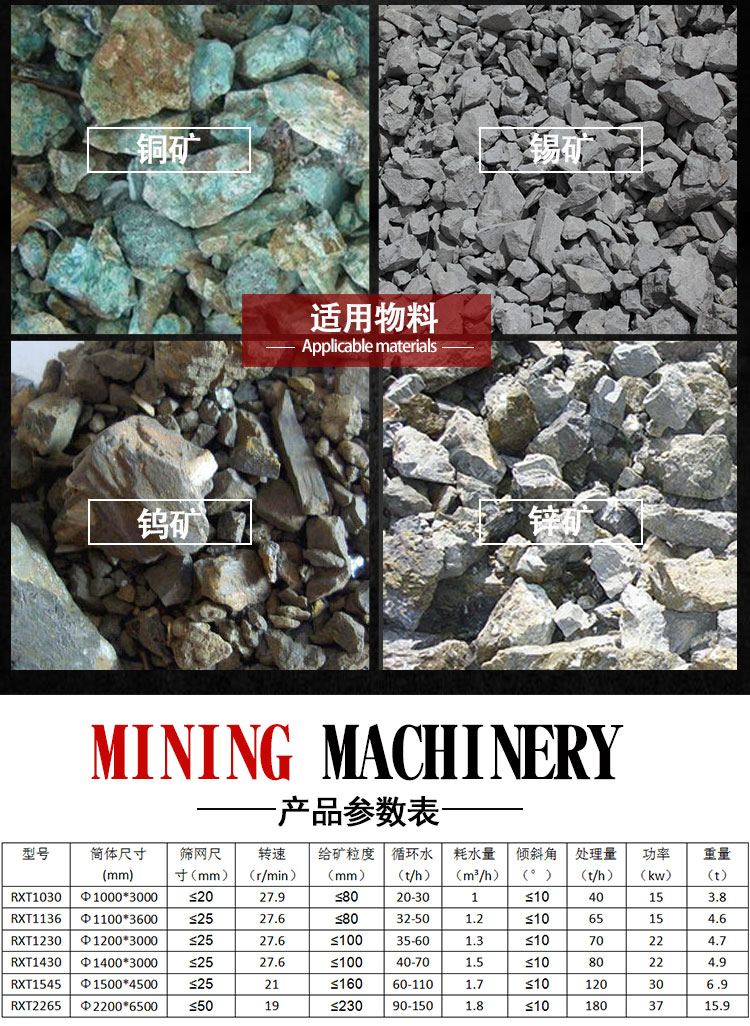

In addition to its different structure, the drum washing machine is no different from other washing machines. Drum washing machine products have a very high degree of cleaning sand and stone, and drum washing machine has also been widely used in many sand and stone production lines. Drum washing machine equipment is mainly used in desliming and screening operations of a large number of sand and stone used in construction sites, sand and stone plants, prefabrication plants and hydropower sites, as well as ore screening operations.

working principle

The cleaning cylinder of the drum washer equipment is supported by four tugs, the motor drives the reducer, and the pinion drives the cleaning cylinder to rotate at a low speed. The aggregate containing mud and stone powder is fed from the feed inlet and enters the rotating drum. The wear-resistant rubber lining plate with a certain angle is installed in the cleaned drum, which is constantly lifted and thrown down. It circulates for many times during the movement from the feed end to the discharge end, and is washed by forward or reverse washing water. The cleaned aggregate is discharged after screening and dehydration by the barrel screen at the discharge end. The wastewater containing sludge flows out through the perforated baffle at the discharge or feeding end.

The1year

The1year

50 integrated mobile single cylin

50 integrated mobile single cylin

Gold mill

Gold mill

Gravity separation coal dressing

Gravity separation coal dressing

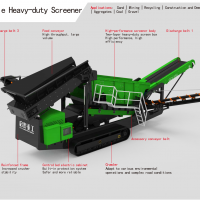

Mobile crusher

Mobile crusher

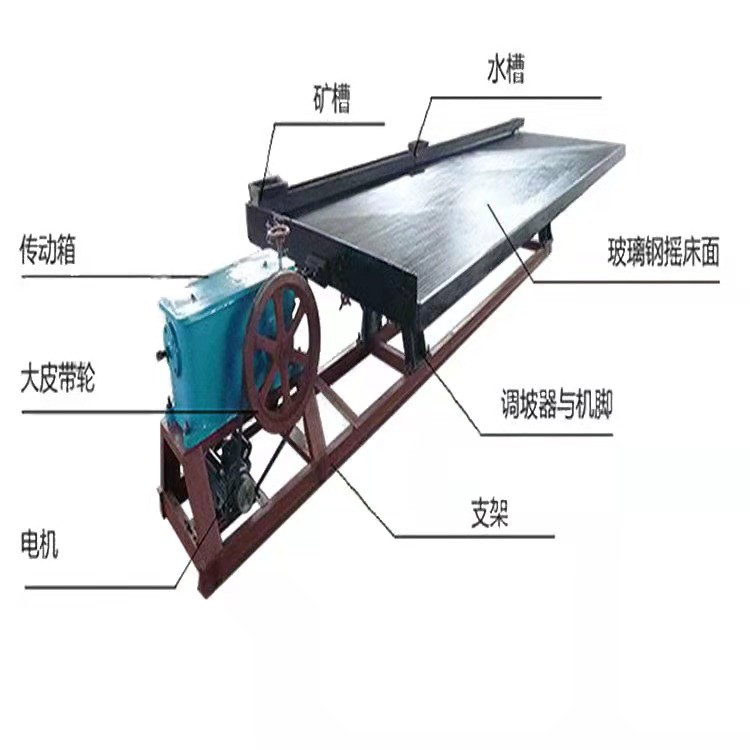

Gold dressing shaker

Gold dressing shaker

Rock gold ore, lead zinc ore, cop

Rock gold ore, lead zinc ore, cop