The design of the taper cross bit includes a sturdy carbide tip that is specifically engineered to withstand the high impact forces encountered when drilling through hard rock formations. This allows for efficient penetration and minimal wear, resulting in faster drilling speeds and reduced downtime.

The tapered shape of the cross bit helps to channel the drilling energy directly into the rock, increasing the effectiveness of each impact. This design also helps to reduce the likelihood of bit deviation, ensuring that the hole stays on the intended trajectory for precise drilling operations.

Proper maintenance of the taper cross bit is essential for maximizing its performance and extending its service life. This includes regular inspections to check for wear, damage, and proper alignment, as well as timely sharpening or replacement of the carbide tip when necessary.

The versatile nature of the taper cross bit allows it to be used in a wide range of drilling applications, from mining and quarrying to construction and geotechnical engineering. Its ability to handle various rock types and formations makes it a valuable tool for many industries.

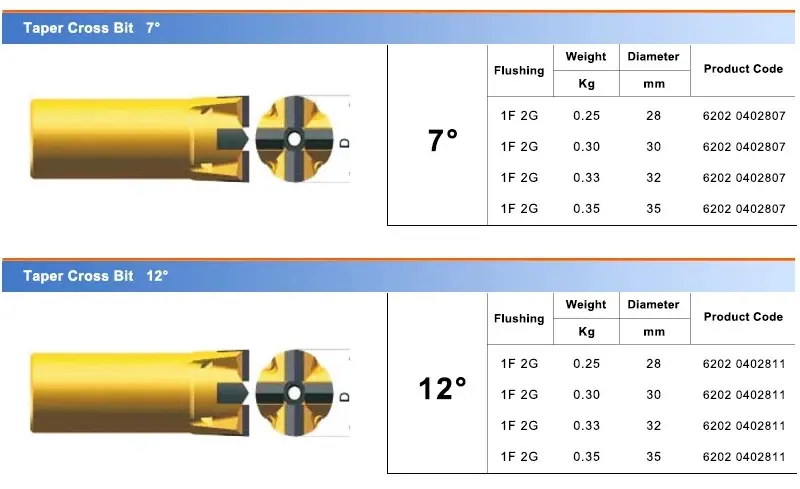

T-cross bits are available in different sizes, ranging from 28mm to 41mm. Usually the taper angle of the bit is 7°, 11° or 12°, depending on the requirements of the drilling rig. The shape of the bit is usually cross-shaped with four cutting edges for efficient drilling.

The1year

The1year

Dome Reaming Bit

Dome Reaming Bit

Impregnated Diamond Core Bits For

Impregnated Diamond Core Bits For

Taper Button Bit

Taper Button Bit

Low Air Pressure DTH Hammer

Low Air Pressure DTH Hammer

Thread Button Bit

Thread Button Bit

Shork Skirt Taper Button Bit

Shork Skirt Taper Button Bit

Pneumatic Rock Drill Accessories

Pneumatic Rock Drill Accessories

HP300 Water Well Drilling Rig

HP300 Water Well Drilling Rig

Trenchers Flat Tooth Foundation D

Trenchers Flat Tooth Foundation D

Taper Drill Tools

Taper Drill Tools