Overview

Quick Details

Warranty:

1 year

Customized support:

OEM, ODM

Brand Name:

DO PUMP

Model Number:

DOH

Place of Origin:

Hebei, China

Application:

metal and Equipment Manufacturers, Mining industry, Sewage mining pump

Horsepower:

20-1600 hp

Power Source:

Electric

Pressure:

1-8 bar, High Pressure sludge pump

Structure:

Single-stage Pump

Outlet Size:

1-18 inch

Voltage:

80/400/415V, etc.

Power:

15-1200 kw, Electric slurry pump

Theory:

Centrifugal Pump

Wet Parts Material:

High chrome alloy and Rubber

Impeller Type:

Open impeller / Closed impeller

Impeller Vanes:

3/5

Pump Model:

NH, HH, M, L, SP, G, ZJ, ZJL, ZGB, TL, WN

Packing:

Plywood Box

Delivery Lead Time:

3-15 days after deposit received

Supply Ability

Supply Ability

200 Piece/Pieces per Month

Packaging & Delivery

Packaging Details

Plywood box or packing according to customers' demands

Port

Tianjin port

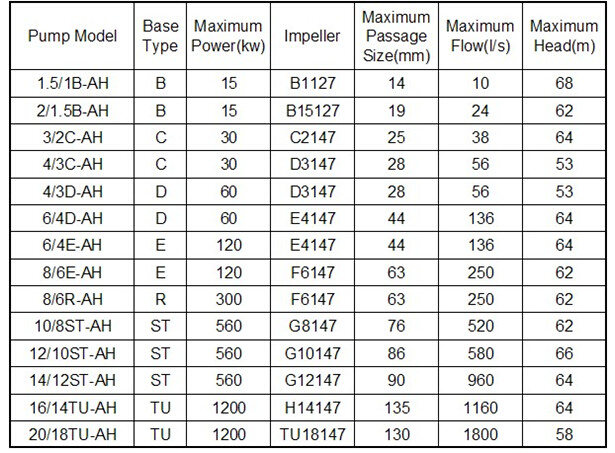

6/4D AH Centrifugal type CRZ Derived Rubber lined Wear-resistant Slurry Pump

Product Description

Product Description :

DOH Series Slurry Pumps Overview | |

Size range (outlet) | 1"to 18"(25mm to 450mm) |

Capacity | up to 22,000gpm(5,000m3/hr) |

Head | up to 240ft (73m) |

Pressure | up to 300psi(2,020KPa) |

DO PUMP BRAND Type of NH series centrifugal slurry pumps are cantilevered,horizontal,slurry pumps.

1. They are designed for the handling highly abrasive, high density slurry in the metallurgical,

mining, coal, power, building material and other industrial departments etc.

2. The pumps of this type also can be installed in multistage series.

3. The frame plates for type NH centrifugal slurry pumps have replaceable wear-resistant

metal liners or rubber liners.

4. The impellers are made of wear resistant chrome alloy or rubber.

5. The frame plate liner and impeller for HH pump are adoptable of wear-resistant metal only .

6. The shaft seals for type NH centrifugal slurry pumps can be adoptable of gland seal or

expeller seal.

7. This Series of Pumps are used conveying abrasive or corrosive slurry, especially clinker of

power plants in electric power, metallurgy, mining, coal, building materials, chemical industry

and other industrial sectors,etc.

High chrome alloy: A05, A07, A49, etc.

Natural rubber: R08, R26, R33, R55, etc.

Silicon Carbide Ceramic .

Other materials can be supplied as requirements .

No. | Name | Material |

1 | Impeller | High-chrome alloy / Silicon Carbide Ceramic |

Natural Rubber | ||

2 | Volute casing | High-chrome alloy / Silicon Carbide Ceramic |

3 | Front liner plate | High-chrome alloy / Silicon Carbide Ceramic |

Natural Rubber | ||

4 | Rear liner plate | High-chrome alloy / Silicon Carbide Ceramic |

Natural Rubber | ||

5 | Liner | High-chrome alloy / Silicon Carbide Ceramic |

6 | Expeller | High-chrome alloy / Silicon Carbide Ceramic |

7 | Shaft sleeve | 3Cr13 / Ceramic Coating |

8 | Water-seal ring | 1Cr18Ni9Ti |

9 | Shaft | 45#steel quenching And high temperature tempering |

10 | Bearing housing | Grey iron |

11 | Expeller ring | High-chrome alloy / Silicon Carbide Ceramic |

Natural Rubber | ||

12 | Front casing | Grey iron or Nodular cast iron |

13 | Rear casing | Grey iron or Nodular cast iron |

14 | base | Grey iron |

15 | Support | QT500-7 |

OEM Service

We also provide OEM service according to customer's special requirements .

Product Application

Testing Equipment

Packaging & Shipping

FAQ

The1year

The1year

15kw 3-phase generator set

15kw 3-phase generator set

Hydraulic Dredge Pump

Hydraulic Dredge Pump

14 Inch Sand Dredge Pump

14 Inch Sand Dredge Pump

Warman 10/8 Slurry Pump

Warman 10/8 Slurry Pump

Hydraulic Sand Dredge Pump

Hydraulic Sand Dredge Pump