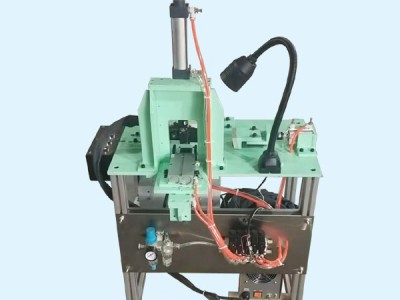

1: Adjust the height of the glue stick (put the product to be glued, make the glue stick contact the product, and then adjust it down by 0.2-0.5mm).

2: Adjust the gap between the gluing stick and the gluing stick (if the contact exceeds 0.2-0.5mm, the gluing thickness can be adjusted according to the gap).

3: Adjust the height of the glue scraping stick (gap 0.00-0.2mm, gap size = glue thickness)

4: Inject glue (dip the glue stick into the glue)

5: Turn on the power supply, turn on the switch and adjust the appropriate speed (the glue stick is about 10% faster than the conveying linear speed)

6: Put in the product, try coating, visually check the gluing amount and coverage state of the product, and then adjust the glue stick up and down.

7: Whether the drying channel temperature adjustment (opening) is opened according to the dry and solid conditions of the products on site

The1year

The1year

Brake pad steel back glue sprayin

Brake pad steel back glue sprayin

Brake pad disc grinder

Brake pad disc grinder

20L Laboratory Mixer

20L Laboratory Mixer

Grooving machine for motorcycle b

Grooving machine for motorcycle b