Automatic Straw Pressing Line Silage Grass Forage Shredder hay and Straw Chopping and Baling Line

Production Description

The combination of heavy waste shredder and baler not only reduces the waste transportation cost, but also convenient to prepare waste for recycling or further disposal.

Key FeaturesDual-Stage Processing: Primary shredding → Secondary fine grinding → Hydraulic baling (customizable sequence).Capacity: 1–50 tons/hour (configurable based on material type: Grass, plastics, paper, textiles, etc.).Bale Output: Compact bales (500–1,200 kg) with uniform dimensions for easy stacking/storage.Automation: PLC-controlled with safety interlocks, optional AI-based sorting pre-shredding.Durability: Hardened steel cutters, 24/7 operation capable, low-maintenance design.

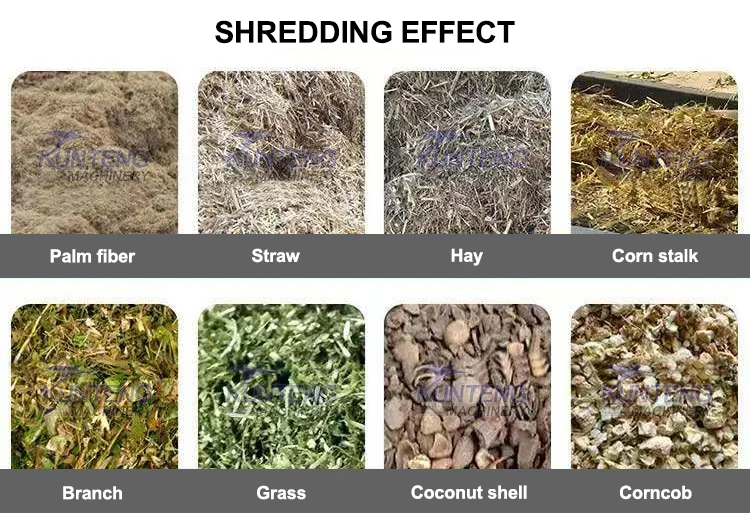

We have many models of Double shaft shredder for meet customers' needs. According to different shred materials, such as Grass, fabric, textile, cloth, glass, foam, household appliances waste, plastic, scrap metal, wood, waste cardboard and so on.

Applications:

✔ Agriculture waste (grass, hay, straw, coconut husk, corn leaf)

✔ Recycling facilities (ePET, plastic, scrap metal, cardboard, aluminum) ✔ Industrial waste (textile scraps, packaging, non-ferrous metals) ✔ MSW volume reduction for landfill diversion.

Application

Our waste shredder and baler suitable for various materials, such as grass, straw, hay, fabric, textile, plastic waste barrels, glass, foam, scrap iron waste, waste wood, waste cardboard, waste bottles, waste cans, waste tires.etc.

Customer Site

Technical Support:

✔ Site design, layout planning, and customized engineering solutions ✔ Equipment manufacturing, the equipments pass through strict test before delivery. ✔ On-site installation, skilled technicians handle assembly, setup, and guide your worker to operate.

✔ Lifetime After-sales service and maintenance.

Products Parameters

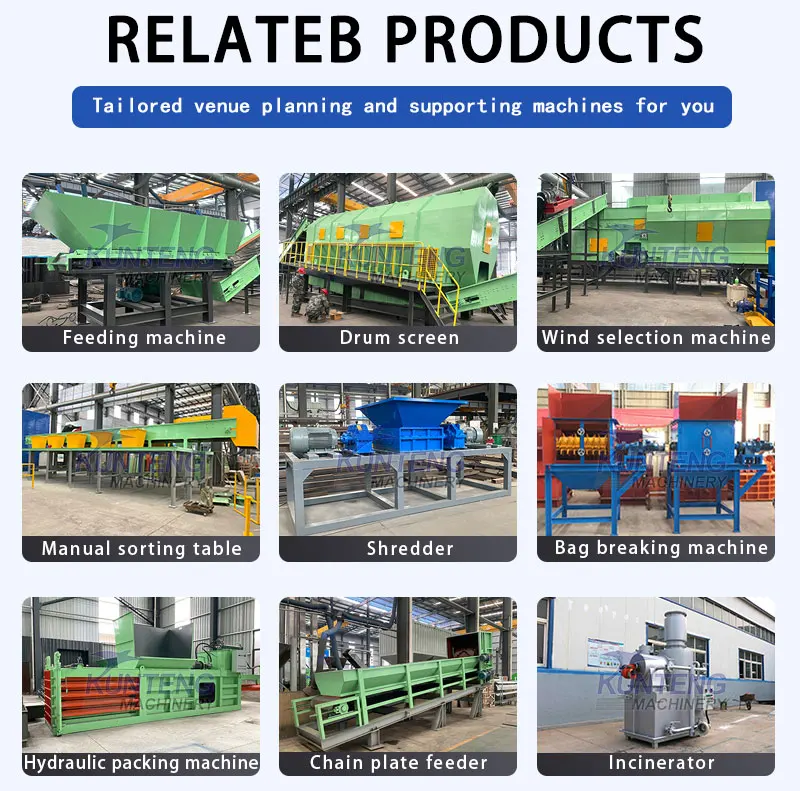

Related products

As a professional manufacturer of waste recycling equipment in China, we have multiple machines to choose:

Waste Shredder / Bag-breaking Machine / Trommel Screen / Magnetic Separator / Eddy-Current Separator /Air Separator / Waste Baler / Optical Sorting Systems / Conveying System / RDF&SRF Making Systems / Composting System / Pyrolysis System.etc.

The main purpose of our waste treatment machinary is to reduce waste and turn it into treasure. Maximize the utilization value of waste. and bring considerable economic benefits to investors.

Company Profile

Henan Kunteng Machinery Manufacturing Co., Ltd.

Kunteng Machinery is established in 1999 and is located in Zhengzhou City, Henan Province, China. Engaged in waste management machinery more than 20 years. The machines are sold to many countries around the world.

Why choose us:

1.We are a comprehensive enterprise integrating R&D, production, sales, and service. We undertakes EPC projects include design the factory building, equipment manufacturing, construction, operation, engineering general contracting, and powerful technical support for the entire project.

2.Our branch companies have spread all over the world(factories in China Gongyi / Shanghai / Singapore / Malaysia / Russia / the United States). Overseas branches provide better after-sales service for customers.

PACKING & SHIPPING

FAQ

Q: What is your Business Model? Trading company or factory?

A:We are a 25 years factory, all our machinery are manufactured by ourselves, factory direct sales, product quality and after-sales service can be guarantee.

Q: What is the Quality of your waste shredder and baler?

A: Our waste shredder and baler passed CE certification, exported to lots countries around the world, such as Australia, Malaysia, India, Italy ,Indonesia, Vietnam, Philippines, Korea, Brazil,Argentina, Russia, South Africa, etc. You can rest assured with the quality absolutely.

Q: What is the Installation of waste shredder and baler?

A: KUNTENG Group has several experienced technicians with passports ready to go for installation, when installation service is needed, the client should pay for technicians' round way air tickets, food and lodging, most importantly to guarantee the technician's safety.

You can send inquiries from this page.once we get your answers,we can provide you the best quotation immediately.