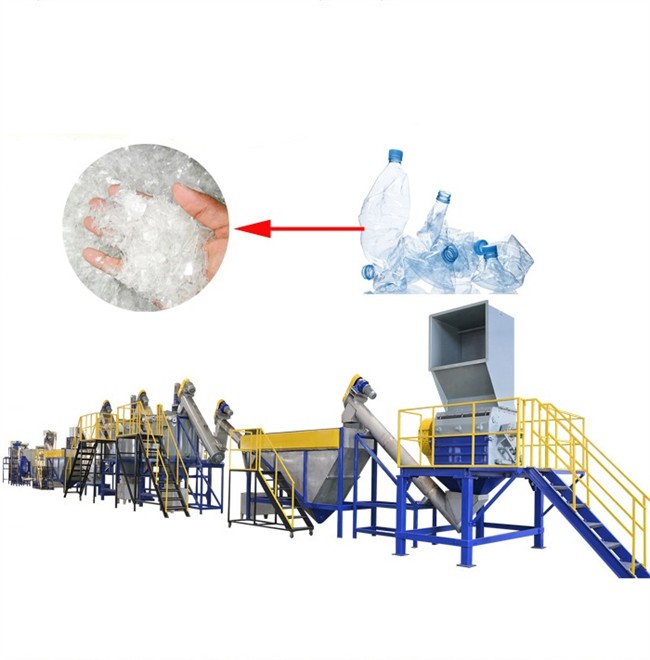

Food Grade waste plastic PET Scrap Bottle Washing Recycling Plant / line / machine

Production Application:

Food Grade waste plastic PET Scrap Bottle Washing Recycling Plant / line / machine

The whole production equipment is researched, design and manufactured by our company, integration of advanced technology, it has features as high efficiency, working stable, large capacity etc. Waste Plastic Pet Bottle Crushing Washing Drying Recycling Line / Machine / Plant is widely used to treat waste plastic, such as PET/PVC/HDPE bottle, water bottles, cola bottle and PET plastic scrap broken into flakes. Pet bottle recycling line is a crushing,washing, drying line. PET flakes are mainly used for the fiber production PET strap, PET sheet, and other related PET products.

With advanced international industry concepts and technologies to meet waste plastic recycling at home or abroad. this line can be displayed "L" or "U" shape .we can also customized the line according the customer's request;1. Realize one production line can process different kinds of raw material; 2. Good quality on our machine(SUS-304 stainless steel, more than 4mm thickness) 3. High quality on final product, low humidity content(Less than 1%) and impurities ( Less than 50PPM).

4.If you want to join the environmental industry,pls feel free to contact with me,tks.

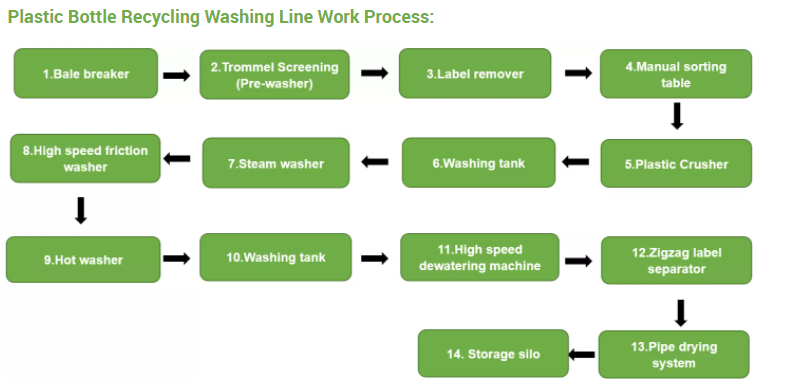

Process Flow:

Machine parameter

| Model | Capacity | Installed Power | Steam Use | Man Power | Area Required |

| WQ-300 | 250-300 KG/H | 150 KW | 150KG | 3 persons/ shift | 29*10*5m |

| WQ-500 | 400-500 KG/H | 250 KW | 200KG | 3 persons/ shift | 35*12*6m |

| WQ-1000 | 800-1000 KG/H | 440 KW | 300KG | 4 persons/ shift | 50*12*6m |

| WQ-1500 | 1300-1500 KG/H | 540 KW | 450KG | 4 persons/ shift | 70*15*6m |

| WQ-2000 | 1800-2000 KG/H | 700 KW | 600KG | 4 persons/ shift | 90*15*6m |

Features:

Capacity: 300—3000kg per hour

Moisture of PET Flakes: Less than 1.5%

Cap &Label: Separate with the PET bottle flakes automatically.

Bottle Types: PET Bottle, Plastic Bucket, Water Bottle, Coke Bottle...etc

Application: PET Strap, PET Yarn Fiber, PET Sheet

Belt Conveyor

Transport PET bottle into rolling separator

Motor power 2.2 kw, with inverter control. Length of belt:4500 mm Width: 800 mm Install isolation stick against-slide on the

surface of belt. Adjust height of conveying belt freely. Small moving wheels are flexible and convenient.

Rolling Separator

Diameter of barrel:1500 mm Length of barrel:4500 mm Motor power:3 kw Rotary speed:<130 RPM Weight: 1800kg Basic material of

barrel Carbon steel coated with metal Zn

Belt Conveyor

Transport PET bottle into label remover.

Motor power 2.2 kw, with inverter control. Width 800 mm Length of belt 4500 mm Install isolation stick against-slide on the

surface of belt. Adjust height of conveying belt freely. Small moving wheels are flexible and convenient.

Label Remover.

Effectively remove labels on the bottle surface.

Motor power 18.5 kw Blower motor 3 kw* 2 Length of the shaft 4000 mm The diameter of the shaft 600 mm Ratio for label removing

80%-90%for pressing bottle 90%-95%for non- pressing bottle

Manual Sorting Table with metal Detector

Manually select bottles that do not meet the requirements.

Width of belt :800 mm Length of sorting table:8000 mm Height:1200 mm Motor power 3 kw, with inverter control.

Shredder & Crusher

Divide large-size raw materials into relatively uniform small-size raw materials through shredding and crushing

Crushing bottle to small flakes.

Screw Loader

Effective length:4000 mm Screw diameter:350 mm Rotating speed:35 RPM Motor power :3 kw Material for contact with PET flake

Stainless steel 304 There will be 1000mm length mesh at the bottom.

High Speed Friction Washer

Preliminarily remove stains and save the amount of hot water.

Motor power: 37 kw Rotary speed of screw:2200 RPM Material for contact with PET flake Stainless steel 304 The machine inside with

water spray system. With a water tank to collect waste water. The paddle inside the friction washer

Hot washing tank

In the case of high temperature and the presence of chemicals, remove oil stains and other dirty things that are difficult to

clean.

Pot diameter φ1800mm Stirring motor power 7.5 kw Heating way Electricity or steam heating Height 2100 mm Material for contact

Floating Washer

Motor power of screw loader 3 kw, with inverter control. Motor power of roller: 2.2 kw Quantity of roller: 2 sets Tank

Dewatering Machine

Most of the water on the surface of bottle flakes is removed by centrifugal force, dehydration rate above 95%.

Label Separator

Removing the remaining label and dust in PET flakes.

Automatic butterfly valve :1.5 kw

Air blower:4 kw

Pipe dry machine

With hot air to dry the bottle flakes.

Packing silo

Function: flakes storage and packing.

Motor power of loading blower: 7.5 kw

Intelligent Control System

With CE/CSA/TUV/SGS/ISO standard, all parameters can be set on the touch screen. 1.Electric control component(Schneider), e

2.All electrical units: LS, Schneider, ABB.

Final bottle flakes