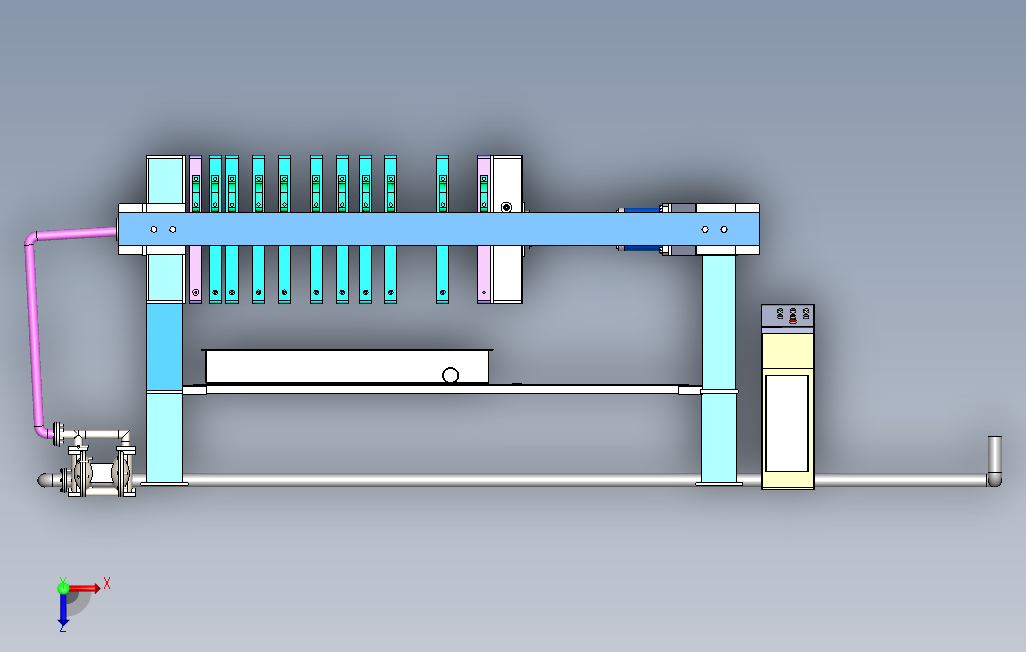

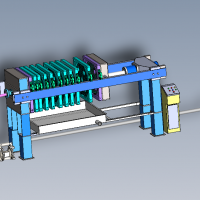

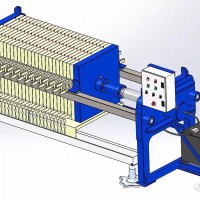

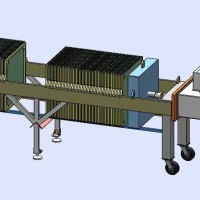

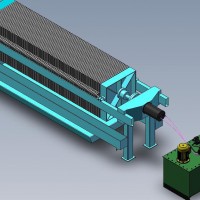

The plate and frame filter press is the first machine used in chemical dehydration.Although the plate and frame filter press is generally operated intermittently, the investment in infrastructure equipment is large, and the filtration capacity is also low, due to its large filtration driving force, high solid content of the filter cake, clear filtrate, high solid recovery rate, and conditioning drugs Due to the advantages of less consumption, it is still widely used in some small sewage plants.After the sludge is concentrated and digested, there is still a moisture content of about 95% to 97%, and the volume is still large.Sludge dewatering can further remove void water and capillary water in the sludge and reduce its volume.After dehydration treatment, the moisture content of sludge can be reduced to 70%~80%, and its volume is 1/10~1/4 of the original volume, which is beneficial to subsequent transportation and treatment.Sludge mechanical dehydration methods include filtration dehydration, centrifugal dehydration and pressing dehydration, etc. Filtration dehydration includes vacuum filtration and pressure filtration; centrifugal dehydration is dewatered by centrifuge; press dehydration is dewatered by screw press or roller press .Commonly used are pressure filtration and centrifugal dehydration methods.Sludge filtration and dehydration uses the pressure difference on both sides of the filter medium as the driving force, so that the sludge moisture is forced to pass through the filter medium to form a filtrate, while the solid particles are trapped on the medium to form a filter cake, so as to achieve the purpose of sludge dewatering.The plate and frame filter press is the first machine used in chemical dehydration.Although the plate and frame filter press is generally operated intermittently, the investment in infrastructure equipment is large, and the filtration capacity is also low, due to its large filtration driving force, high solid content of the filter cake, clear filtrate, high solid recovery rate, and conditioning drugs The advantages of high consumption are still widely used in some small sewage plants.During the dehydration process, the plate and the frame are arranged alternately, and the two sides of the filter plate are covered with filter cloth.There is a small hole in the middle of the upper end of the plate and the frame. After pressing, it becomes a channel. The sludge pressurized to 0.2~0.4MPa enters the filter press chamber through the channel. The surface of the filter plate is engraved with grooves. There are holes for the filtrate to be discharged. Under the pressure, the filtrate is discharged through the filter cloth, along the grooves and holes, and the sludge is dehydrated.Automatic plate and frame filter presses have been developed at home and abroad.The plate and frame filter press can withstand higher sludge specific resistance than the vacuum filter, so that the consumption of conditioner can be reduced, and cheaper chemicals (such as FeSO4 7H2O) can be used.When the specific resistance of sludge is 5×1011~8×1012m/kg, it can be filtered directly without preconditioning.The mud cake yield and mud cake moisture content of the plate and frame filter press shall be determined according to test data or similar operating experience.The moisture content of mud cake can generally be 75%~80%.Design requirements of the plate and frame filter press (1) The filtration pressure is 0.4~0.6MPa (about 4~6kg/cm2); (2) The filtration period is not more than 4h; (3) Each filter can be set with a sludge pressure One pump should be used, and the pump should be a plunger type; (4) The amount of compressed air should not be less than 2m3/min per 1m3 filter chamber (according to standard conditions); (5) Good ventilation and high-pressure flushing should be paid to the dehydration of the plate and frame System, sludge mill settings before conditioning, and mud cake crusher settings after pressure filtration, etc.The design method of filter press dehydration is mainly to calculate the yield of mud cake, the required area and number of filter presses according to the sludge treatment capacity, dewatered sludge concentration, filter press working procedure, and filter press pressure.According to the calculated filter press dehydration area A, the plate and frame filter press is selected.At least 2~3 sets are selected, and a complete set of equipment is arranged in the dehydration workshop.

Plate and frame filter press