High Speed High Rigidity Vertical CNC Machining Center VMC 850 High Precision

Description of Vertical CNC Machining Center

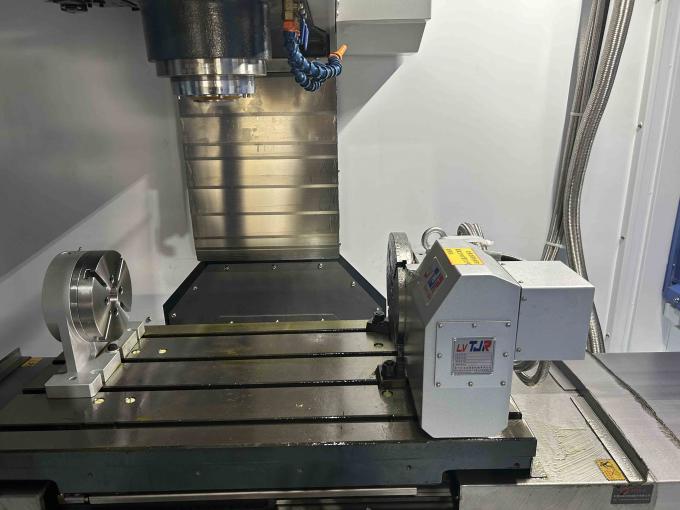

1.Vertical machining center widely used for processing flat face, slope face, keyway, key groove, slot and drilling,reaming, boring in almost every country all over the world because of the high quality with competitive price.

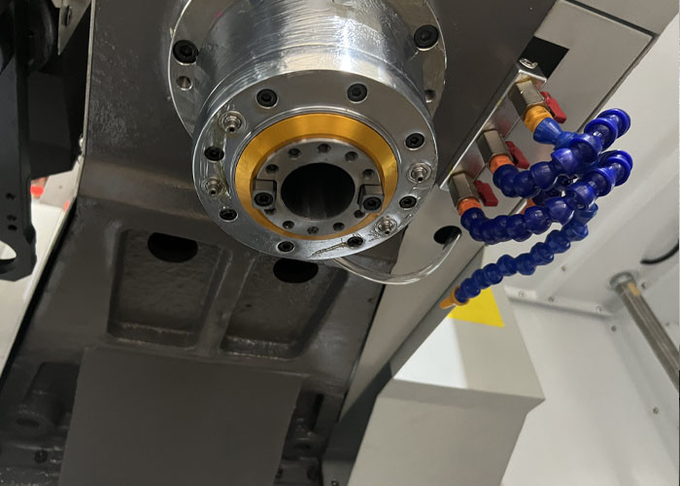

Taiwan original milling head and 3 axes Taiwan leadscrews make sure our milling machines performance better than others.

The motor bracket and screw supporting bearing house are built as one casting, the super long assembling contact plane makes the bracket connect tightly with the base, this make screw move with high rigidity and stability.

High strength casting technology the foundation, column, and main spindle box, cross sliding table, worktable and other parts were designed with high strength casting technology. The structure of machine is very steady. The casting parts show rational geometry composition through machine tool kinetics and finite element analysis.

The CNC milling machine normally are packed by the fumigation wooden pallet which is easy for clients to transport or load and unload.

2.Taiwan precision screw rod and Taiwan precision lock nut are adopted. The lead screw bearing adopts Japanese NSK bearing, which is directly connected with flexible coupling, with small back clearance, sensitive transmission and high precision.

3.According to the finite element analysis of the main structure, the machine base, spindle box, cross slide table, worktable, etc. are made of high-quality HT250 precision casting, which can ensure the stability of long-term processing after secondary failure treatment.

Main Technical Parameters

| ITEM | MODELS | VMC850 |

| WORKTABLE (WIDTH*LENGTH) | mm | 1000x500 |

| DISTANCE BETWEEN T SLOTS | mm | 5-18x100 |

| MAX LOAD BEARING OF WORKTABLE | kg | 600 |

| X/Y/Z AXIS TRAVEL | mm | 800/500/500 |

| 4-AXIS | - | 200 |

DISTANCE FROM SPINDLE NOSE TOWORKBENCH | mm | 110-810/110-610 |

| SPINDLE HOLE TAPER | - | BT40 |

| SPINDLE SPEED RANGE | r/min | 10000 |

| TRANSMISSION OF SPINDLE BOX | BELT/DIRECT | BELT/DIRECT |

| SPINDLE MOTOR POWER | kW | 7.5 |

| X/Y/Z RAPID FEED SPEED | m/min | 48/48/48 |

| MAX CUTTING FEED SPEED | mm/min | 12000 |

| TOOLS MAGAZINE CAPACITY | pcs | 24 |

| X/Y/Z POSITION ACCURACY | mm | 0.005 |

| X/Y/Z RE-POSITION ACCURACY | mm | 0.003 |

| MACHINE WEIGHT | kg | 5000 |

Standard Configuration for VMC Series

Full Cover shield / Self-lubrication system / Working lights / Warning lights / Working condition warning lights / Self-powered electrical shutoff system / Clean air gun/ Water Tank / Transformer / Spindle air curtain and dust control system / 10000 RPM spindle / Worktable cleaning water gun

Optional Configuration for VMC Series

24 disc manipulator tool magazine / Crawler chips remover / NC rotary table (4 Axis) / CTS / Tool detection system / AJO / 12000 & 15000 RPM Direct connection spindle / Oil mist purifier

Gallery of The Machine

FAQ

1. Is it all right to make customer's own brand name?

A: yes. we are available with OEM

2. Are you a manufactuer or trading company?

A:We are the manufacturer

3. Can you do the design for us?

A: yes. if you want a different control system design or higher column , we are available.

4 . What is your terms of delivery?

A: FOB shenzhen.

5. What's your payment term?

A: T/T OR L/C at sight.