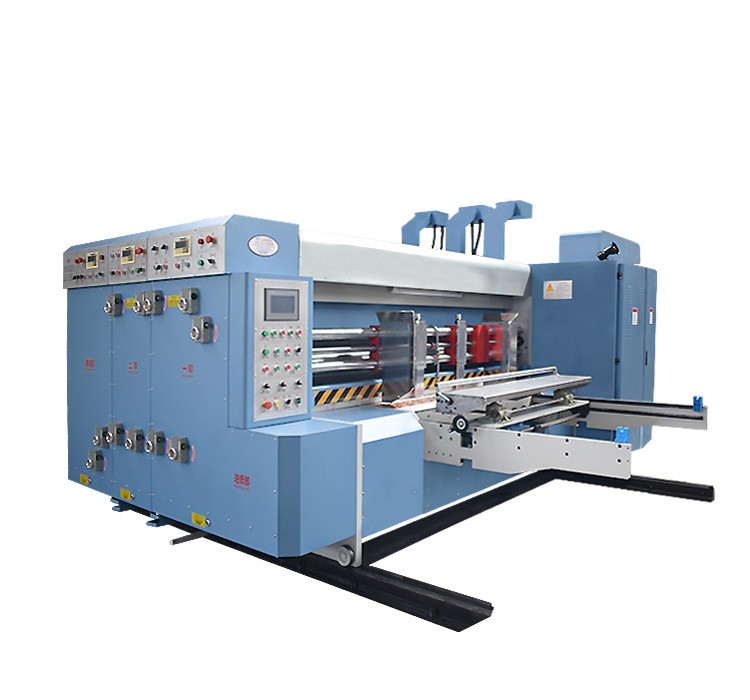

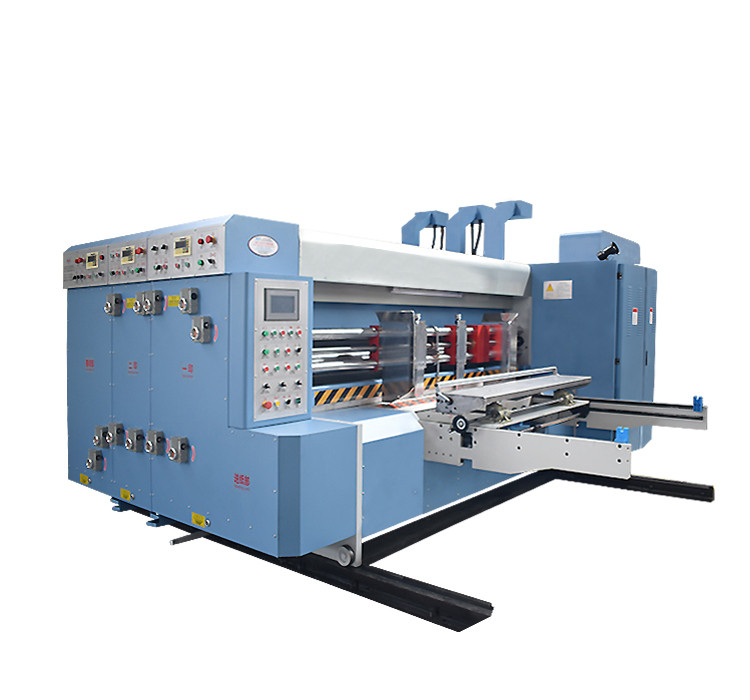

flexo printing machine manufacturer 4 colors flexo printing machine for carton box

Automatic paper feeding, medium speed machine, machine size can be customized

Optional slotting part and die cutting part.

Economical printing machine . Competitive price.

Professional carton printing machine manufacturer.

Perfect quality inspection system and after-sales service system.

Multiple quality certification and honor certification.

Function and characteristic

1. l electrical and pneumatic components are international famous brands with stable and reliable quality

2. l all transmission gears are 40Cr.

3. l the transmission parts (shaft and tooth joint) are keyless.

4. l transmission bearings and important transmission components are famous brands in China.

5. l the lubrication system of the whole machine adopts spray type automatic lubrication.

6. l the main fan adopts frequency conversion control.

7. l the cutting part of the circular die and the slotted part of the wheel are optional.

8. l optional: ceramic anilox roller, stacker.

The Machine technique parameter:

1 |

Color group | to be configured according to user’s needs | ||

2 | Printing paper | A,B,C,A/B,B/C and A/B/C type corrugated paperboard(the maximum interval 11mm) | ||

3 | Width of machine inside | 2600mm | 2800mm | 3000mm |

4 | max.paper size | 1200×2400mm | 1400 ×2600mm | 1600×2800mm |

5 | Max.printing size | 1200×2300mm | 1400 ×2500mm | 1600×2600mm |

6 | Skip feeding paper | 1400×2400mm | 1600 ×2600 | 1800×2800 |

8 | Printing plate thickness | 7.2mm | 7.2mm | 7.2mm |

9 | Design speed(piece/min) | 180pcs/min | 150pcs/min | 150pcs/min |

10 | Economic speed(piece/min) | 80-160pcs/min | 80-130pcs/min | 80-100pcs/min |

11 | Tinted precision | ±0.5mm | ±0.5mm | ±0.5mm |

12 | Slotting precision | ±1.5mm | ±1.5mm | ±1.5mm |

13 | Max.slotting depth | 7×300mm | 7×350mm | 7×400mm |

increase the blade, increase the slot depth | ||||

14 | positive knife Min. Slot distance negative knife

| 170×170×170×170mm 280×80×280×80mm | 170×170×170×170mm 280×80×280×80mm | 170×170×170×170mm 260×90×280×80mm |

15 | Max.die-cutting size | 1200×2300mmmm | 1400×2500mm | 1600×2700mm |

16 | Printing plate diameter(contain plate thickness) | ɸ405mm | ɸ480mm | ɸ530mm |

Feeding & printing unit

1. The air suction auxiliary paper feeding fan is 7.5kW, and the air volume can be adjusted according to the different bending degree of the paperboard to ensure smooth paper feeding.

2. The side baffle is adjusted electrically, and the front baffle and rear baffle box are adjusted manually.

3. Seven inch computer touch screen control (display production volume, count alarm, phase adjustment).

4. The brush dust removal device of the paper feeding department can remove a large number of impurities on the printing surface of the paperboard and improve the printing quality.

5. Printing department: (1-4 color printing is optional)

6. Printing roller: optional outer diameter: 300mm, 405mm, 480mm, 530mm.

7. The outer diameter of steel anilox roller is ɸ 197.4mm (mesh: 180, 200, 220, 240, 260). (mesh optional) rubber roller: outer diameter ɸ 197.4mm。

8. The anilox roller is attached with a wedge type overrunning clutch, which is convenient and fast in ink leveling and washing.

9. The chequer gap dial is adjusted manually.

10. Phase adjustment mechanism: printing phase electric digital 360 degree adjustment (both operation and stop can be adjusted).

Manually adjust the lateral position and adjust the distance ± 10mm.5)

Die cutting unit:

1. Rubber roller: centrifugal casting steel cylinder. The rubber pad adopts German brand.

2. The rubber pad of die-cutting roll adopts German brand.

3. Die cutting roller phase and axial adjustment, PLC touch screen control, electric digital 360 degree adjustment.

4. The rubber pad roller is a cutting and repairing mechanism, and the rubber pad can be reused for many times.

5. The differential compensation device can automatically adjust the number of revolutions of the rubber buffer roll.

6. The mechanical transverse ± 40mm swimming device of rubber cushion roller improves the service life of die-cutting rubber cushion.