Sesame processing plant

Features:

1. Less manual investment and high automation degree.

2. Good working environment

Sesame seed cleaning and peeling plant plays an important role in sesame

processing project, It can peel white or black sesame seeds efficiently and

with large processing quantity so as to improve sesame economic benefits

and utilization value. The sesame seed peeling machine has vertical structure,

low rate of repair and maintenance and is easily operated. The whole

sesame seed cleaning and peeling plant needs alkaline water to soak

the raw material and separate sesame skin and kernel by washing.

Therefore, this process is also called wet method cleaning and peeling

technological process.

Sesame seed cleaning and peeling plant procedures are listed as below:

Raw sesame seeds - Cleaning up - Soaking - Skin removing - Skin and kernel

Separation- Dehydration - Drying - Selecting - Packing - End product

Cleaning: to remove the big and small impurities, stones and sand by

grain cleaning and destoner machine; to remove the metallics by

magnetic separation equipment so as to improve sesame purity.

Removing the sesame that is not full: to remove by rotary sieve.

Color sorter: to remove the kernels with different colors by computer

color sorter.

Sesame grading: to select similar sesame by classifying equipment.

Soaking: to convey sesame to blender by transmitting tube according to

1.3% caustic soda flakes and sesame gravity and soak sesame for 20-30

minutes in water.

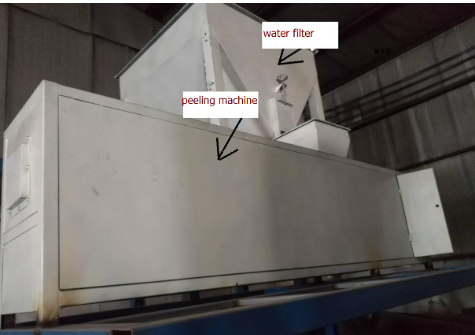

Peeling: to adopt vertical cylinder peeler and make sesame have relative

movement in the container. To remove the sesame skin by making use of

the friction among the sesame seeds.

Separation of skin and kernel: to make the sesame skin soften by adopting

the best soaking

technology. To separate the skin and kernel by using the volume difference

between sesame skin and kernel. In the automatic separator with sinking

structure, the water flow can take sesame skin away and kernels are left.

Drying: Sesame and water gravity ratio: 1:2; throwing for 15-20 minutes,

drying and entering into centrifugal machine; drying for 5-10 minutes

under 120℃; then conveying finished products to the end products

warehouse.

Sesame Seed Cleaning and Peeling Plant Design:

The sesame cleaning and peeling plant is with vertical structure, fully

and effectively used internal space, small volume, simple structure,

easy to operate, and low rate of repair and maintenance, with short

process time for soak, hull remove and separation, and with high

production efficiency and high product yield.