1450 Full Automatic Multilayer Flute Laminator

Introduction

Our company specializes in the production of fully automatic paper laminating machines, used in the printing and packaging industry for cardboard + corrugated paper + corrugated paper. Applicable corrugations are A, B, C, E, F, N, three-layer, five-layer, and seven-layer. It can work normally, the laminated paper has good flatness and high precision, which reduces the customer's purchase cost.

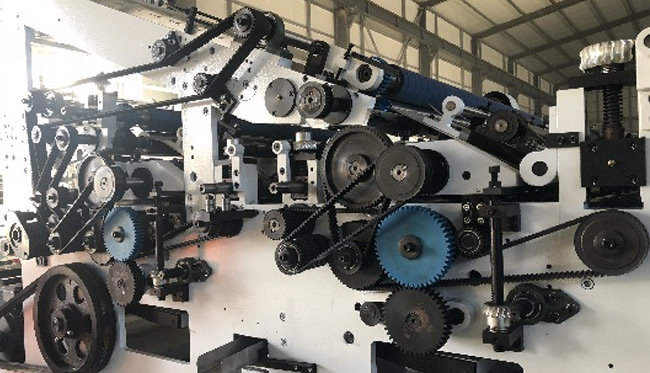

The main parts and components of the whole machine adopt original products from well-known domestic manufacturers, with long life and good stability. The electrical part adopts world-renowned brands, and the bearings of the whole machine are imported bearings. The drums of the whole machine have been corrected for dynamic and static balance, ensuring the stable performance of the whole machine.

The whole machine has the advantages of good stability, accurate mounting, easy operation, low wear, time saving, labor saving, and easy maintenance.

Adopt the uniquely designed paper feed head, which can suck the air forcefully, feed the paper smoothly, and stably

The unique synchronous belt paper feeding mechanism can realize the smooth and accurate conveying of cardboard of more than 300 grams and A, B, C, E, F, N corrugated and three-layer, five-layer and seven-layer corrugated cardboard.

imported synchronous belt is used as the transmission part, which is soft, strong, durable, wear-resistant, tensile-resistant and heat-resistant. It guarantees synchronization accuracy with the synchronous pulley. The lamination error can be controlled within ±1.5mm, and the paper damage rate can be reduced.